SEA Electronics, SCAIME's partner in Tunisia, is an engineering company specializing in industrial process automation.

SEA designs and implements special machines and production, assembly or packaging lines.

The customer wanted to modernize two packaging lines of lubricant cans.

The system, based on the analog processing of the weight measurements and the filling management by the PLC, was no longer precise enough:

To view this content, you must enable youtube cookies

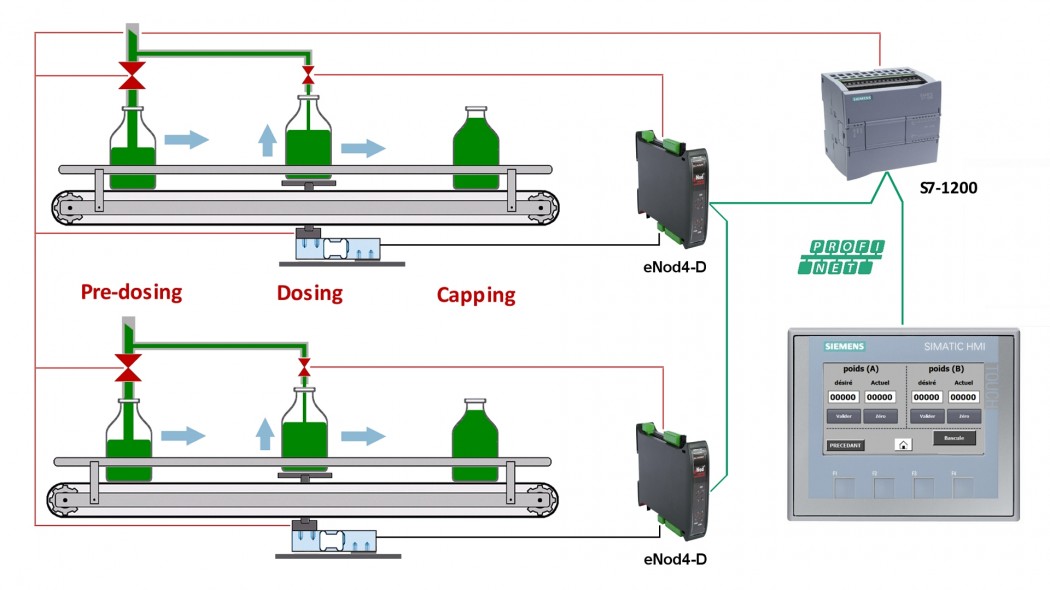

The packaging line supports the labeling, filling and capping of lubricant bottles.

To improve filling rate and dosing accuracy, SEA has chosen to:

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

In this architecture, the S7-1200 PLC controls the overall operation of the 2 packaging lines: Pre-dosing by time, labeling and capping bottles.

Each eNod4-D controller supports:

Filling, Dosing controller

Filling, Dosing controller

High accuracy stainless steel load cell, 7.5 kg ... 125 kg