RMIS is a manufacturer of bagging and dosing machines based in France. RMIS has built its reputation on dosing powders and granules for agriculture, waste treatment, cement, fertilisers and quarries.

RMIS needed to design a very fast automated system for filling bags of sand with capacities varying from 2 to 40 kg.

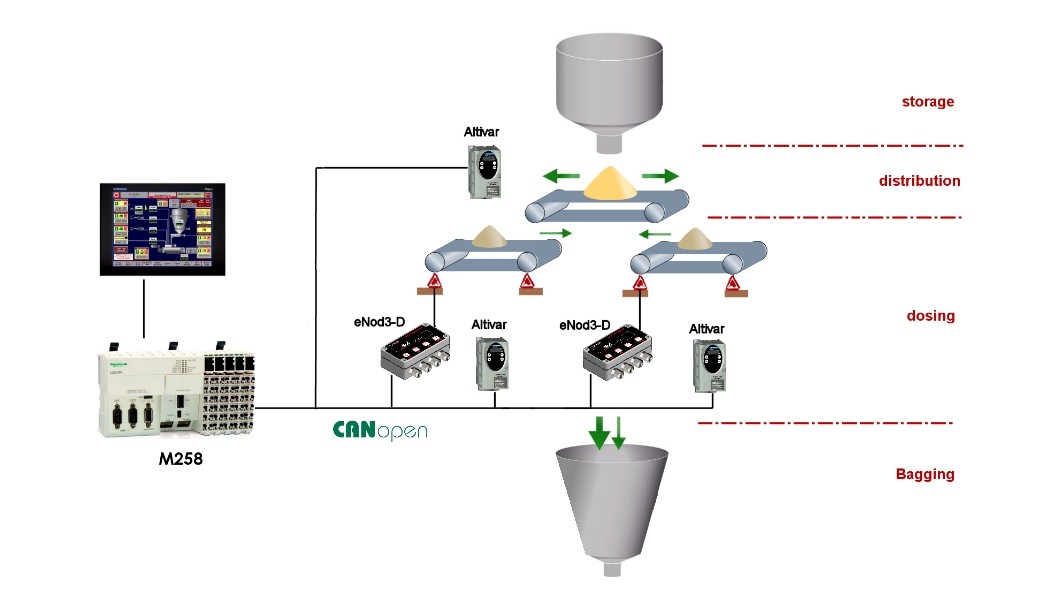

The sand is stored in a hopper and dosed alternately on two conveyor belts equipped with load cells. Each dosed batch is then transferred into a bag to be sealed.

SCAIME provided a solution with Schneider Electric.

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

In this solution, an M258 PLC manages alternating doses to optimise the bagging speed. The eNod3-Ds are responsible for controlling the doses on each conveyor belt. At the end of the dosing cycle, the eNod3-D transfers the batch into the bagging system.

Stainless steel bending beam load cell, 5 kg ... 500 kg

Mounting with damper for F60X, 10 kg ... 300 kg

Filling, Dosing controller

Filling, Dosing controller

Filling, Dosing controller