Revet Recycling is an Italian manufacturing company that manages the recycling of mixed plastics through a profile production plant and granule production plant.

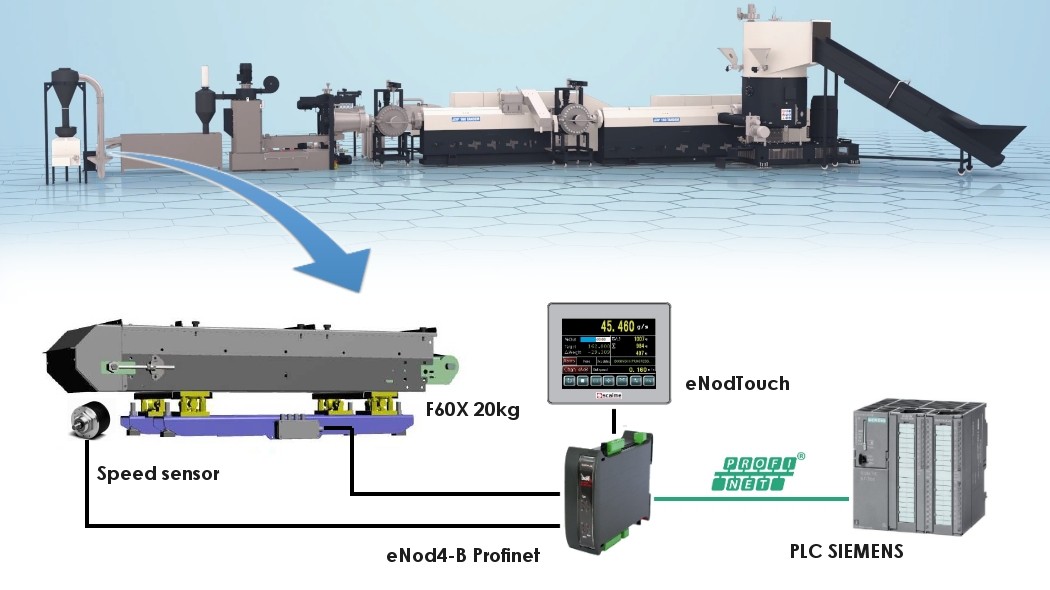

To equip a Gamma Meccanica recycling line consisting of a grinder, extruder, and granulator, Revet Recycling was looking for a system able to continuously monitor the production of granules at the extruder output:

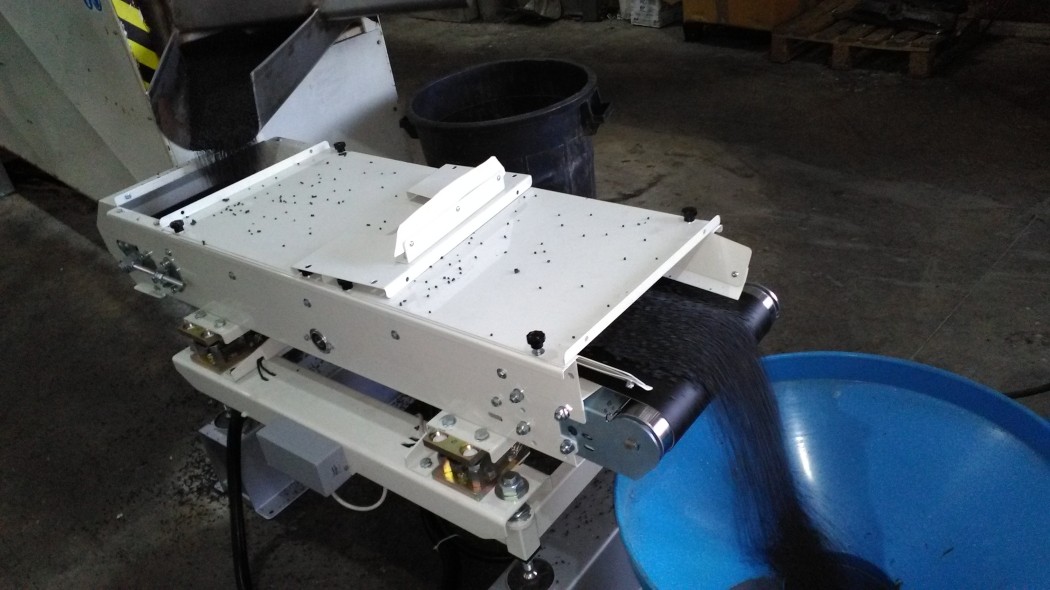

SCAIME and its partner in Italy, the system integrator NONIS Srl, proposed a conveyor belt weighing system equipped with F60X load cells. This load receptor is controlled by an eNod4-B continuous weighing transmitter which takes in charge the flow rate measurement and the continuous totalization of the product.

The weighing data are transmitted by eNod4 to the PLC thought the customer's PROFINET network.

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

Continuous weighing, Belt scales, Belt weigh feeders

Continuous weighing, Belt scales, Belt weigh feeders