Process Poudres Innovations (PPI) is a designer and manufacturer of storage, transfer and dosing facilities for powders and granules.

PPI builds turnkey machines and installations for all manufacturers who have to handle powders or granules.

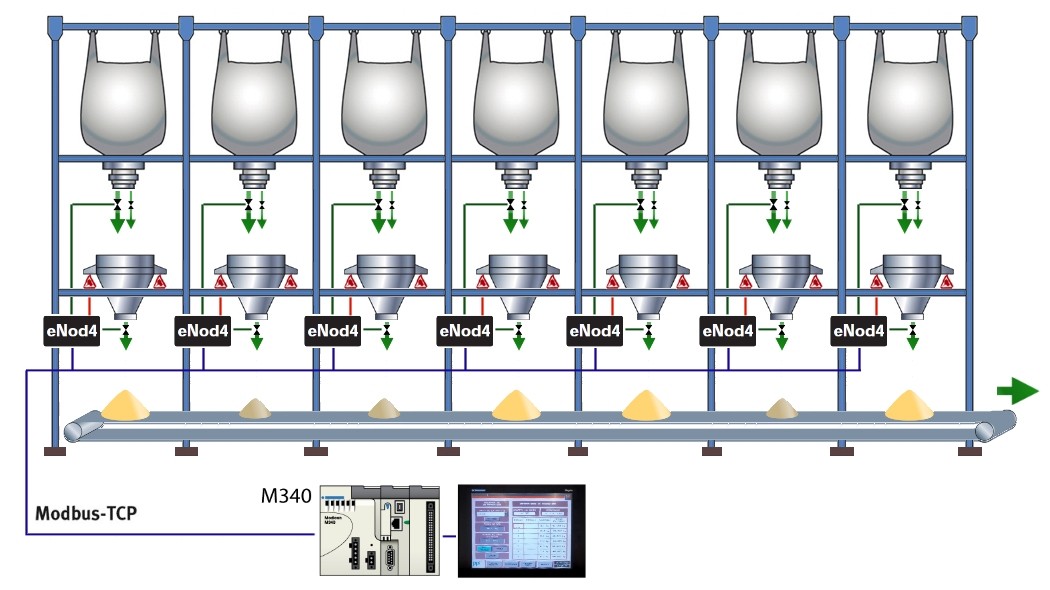

For a manufacturer of custom concrete, PPI had to design a storage, dosing and mixing facility of 7 ingredients made up of powders and granules. The mixture, produced with an accuracy of ± 10 g, feeds a bagging machine for packaging in 30 kg bags.

To view this content, you must enable youtube cookies

PPI has designed a fully automated system for big bag storage, dosing and mixing of ingredients. The system uses SCAIME weighing components integrated into the Schneider Electric Ecostruxure automation architecture.

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

The dosing system consists of 7 hoppers weighed by F60X load cells mounted on RUBBERKIT damper kits.

In this architecture, the M340 PLC handles the overall system control and management formulas, while the dosing tasks are assigned to the controllers SCAIME eNod4-D.

Each eNod4 manages the filling of weighed hoppers. At the end of dosing, the M340 controls the transfer of ingredients to the bagging machine.

The connectivity between the eNod4 controllers and the M340 controller has been validated as part of the technological partnership between SCAIME and Schneider Electric for weighing applications.

Stainless steel bending beam load cell, 5 kg ... 500 kg

Mounting with damper for F60X, 10 kg ... 300 kg

Filling, Dosing controller