For over 70 years, Hema (a subsidiary of Pneumatic Scale Angelus) has specialised in filling complex products and liquids, including smooth, chunky, pasty, viscous, stringy and foaming products.

A subsidiary of Pneumatic Scale Angelus, HEMA operates in 90 countries and is a market leader in volumetric and weight-filling (linear or rotational) technologies.

To equip its new generation of machines, HEMA wanted a precise, robust and extremely reliable load cell to meet the efficiency criteria of a production line.

HEMA was also looking for a load cell with a hygienic design and EHEDG certification.

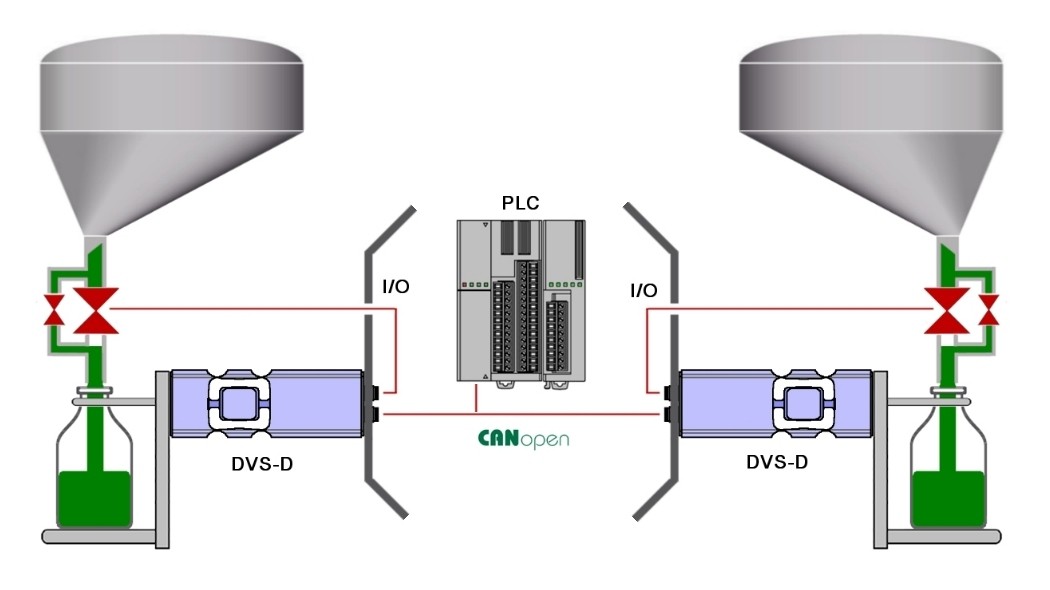

SCAIME developed, in collaboration with HEMA, the DVS, a stainless steel digital sensor dedicated to filling control. Constructed without any flat horizontal surface or sharp edge, the design of the DVS is certified by the EHEDG (European Hygienic Engineering and Design Group).

The DVS has an onboard controller which processes the signal and manages the filling procedure. It offers several digital filters for the elimination of vibrations, and a dosing algorithm specially optimised for filling machines with a very high output rate.

In a context of increasingly high food safety standards, the DVS is our response to the needs expressed by our customers:

To view this content, you must enable youtube cookies