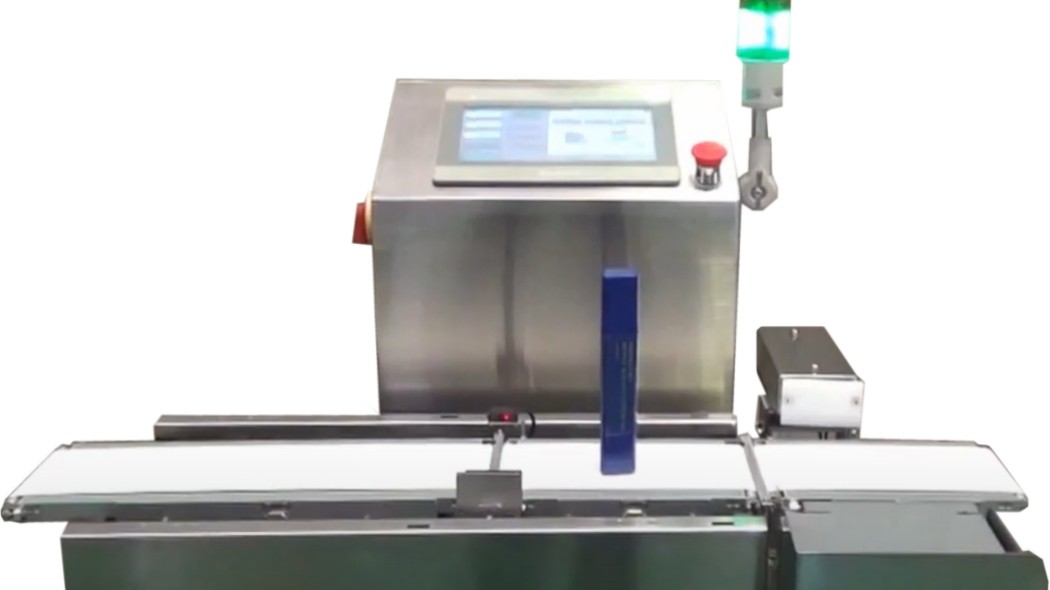

Taiwan-based machine manufacturer, Wintech Automatic focuses on the smart factory transition in the manufacturing industry. Wintech designs or integrates checkweighers, filling machines and robotic arms for the food, pharmaceutical or cosmetic industries.

As part of Industry 4.0, these machines are connected to an intelligent cloud system developed by Wintech. This real-time monitoring system features high accuracy to ensure product quality and stability in high-speed production.

SCAIME and its partner SCIENSPEC in Taiwan, provide Wintech with the weighing components to equip their high-speed checkweighers.

For the development of a new generation of dynamic checkweigher, SCAIME accompanied Wintech for the choice of the load cell and weighing transmitter allowing to obtain a high precision with a high weighing rate.

Intended mainly for the control of pharmaceutical or cosmetic products, the checkweigher had to reach an accuracy of up to ±0.1g with a speed of 80 products per minute.

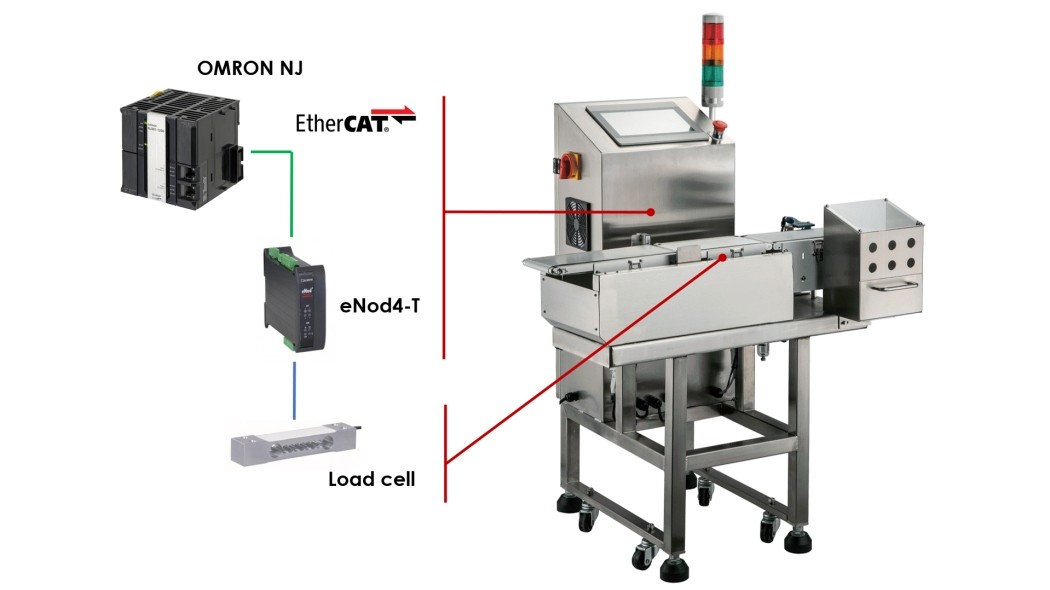

The weighing controller had to be able to connect to the industrial EtherCAT network, which Wintech chose for its high-speed data communication capability.

To view this content, you must enable youtube cookies

To meet the customer's needs, SCAIME proposed a weighing system integrated to the WINTECH checkweigher automation.

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

This system consists of a single point load cell connected to an enod4-T weighing controller.

eNod4-T controller is responsible for the load cell signal processing and transmitting the measurement to the PLC via the EtherCAT network. This connectivity offers a complete integration of the weighing system which can be controlled by the PLC.

Thanks to its high measuring frequency and digital filtering capabilities, eNod4-T provides stable weight measurements with a very high resolution. The weight measurements are then transmitted to the PLC via the EtherCAT network.

This fast acquisition of the measurements filtered by eNod4-T, allows the PLC to determine the weight of the product to be controlled with a high accuracy and a high rate. The determination of the weight is carried out by an exclusive algorithm developed by Wintech.

Weighing transmitter