This application was developed for BRALIMA brewery in Kinshasa. This production unit is the leader of beer and soft drink in Congo.

The engineering was performed by EGELEC, a Schneider Electric system integrator in Kinshasa.

The project was to modernize the manufacturing process:

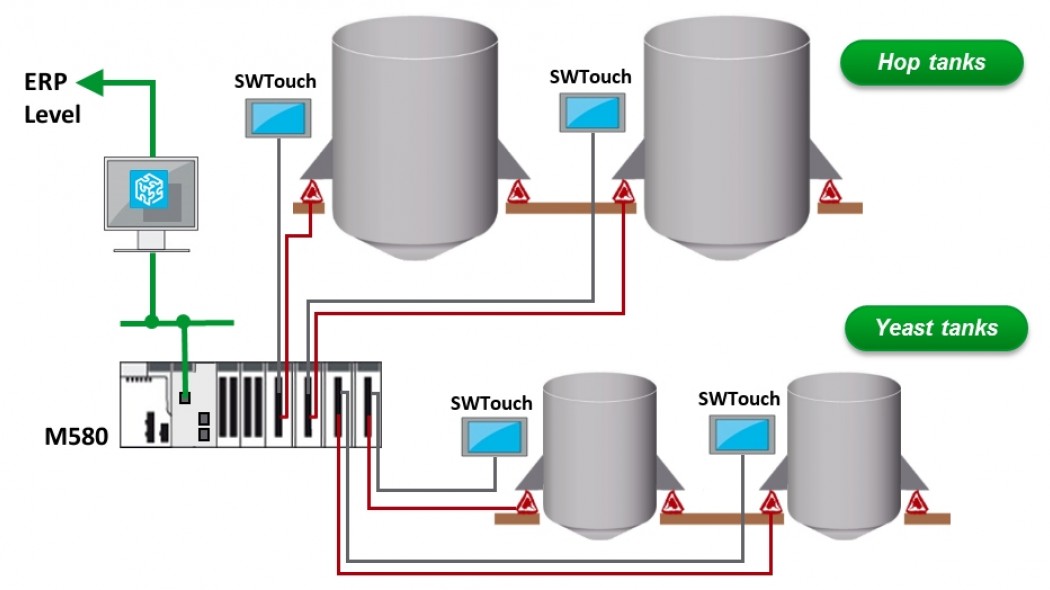

SCAIME provides a solution with Schneider Electric in the framework of a formal collaborative program. The solution includes 4 weighing systems for yeast and hop tank level monitoring.

|

| |

|---|---|---|

| SCAIME PRODUCTS | AUTOMATION PRODUCTS | |

Weighing module for PLC Schneider Electric M580

Human Machine Interface for PMESWT