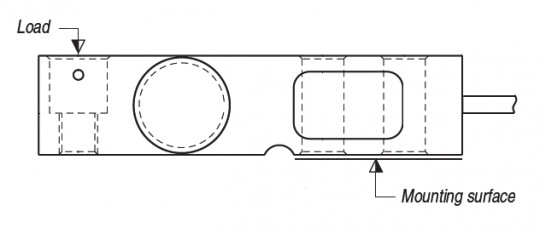

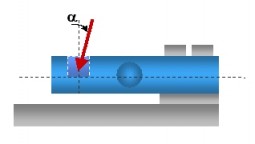

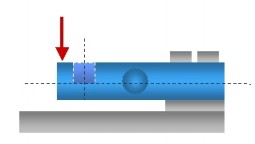

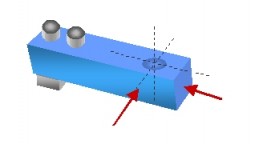

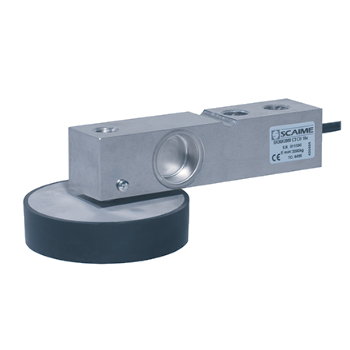

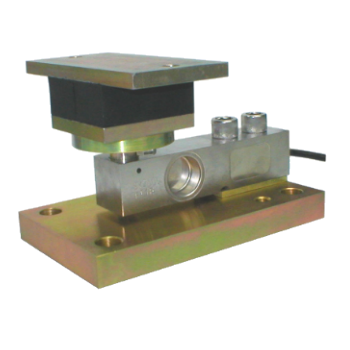

This load cell is bolted to a fixed structure at one end and force is applied through a single point at the other end, causing the beam to bend and placing the strain gauge area under shear.

Shear as a measuring principle offers a good resistance against side loads and small sensitivity to the variation of loading position.