Wind and seismic forces can have a great effect on outdoor weighing system. Upward, downward, and shear forces are exerted on load cells.

The effect of wind are complex and depend on factors such as the degree of exposure, local topography and maximum wind speed.

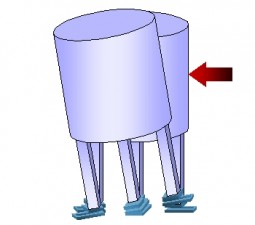

Wind striking an exposed tank or silo will generate a side force which causes an overturning moment and a smaller vertical force.

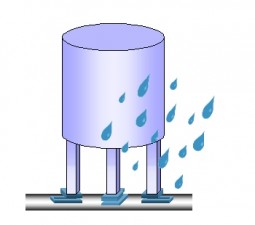

Moisture and corrosive substances can damage the cells physically and by shorting out its electronics. Debris collected on the load cells will cause weighing errors by mechanically binding the scale.

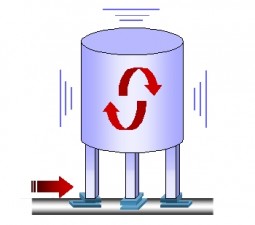

Caused by the surrounding environment or mixer’s agitation, vibration Induces electrical noise on the load cell’s signal.

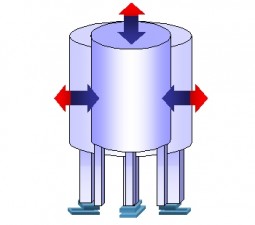

Temperature can affect a load cell by causing structural supports to expand and contract or by exceeding the operating limits of the load cell.

As a tank expands and contracts, it pushes or pulls on attached piping. If the piping connections are rigid, this can cause weighing errors.

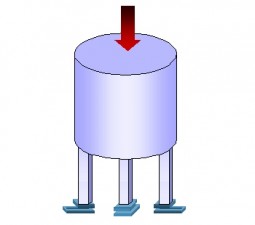

A load dropped on the scale from above can exert strong forces that can damage the load cells.

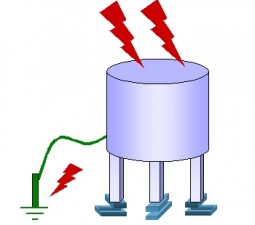

Electrical surges can cause permanent damage to the load cells. Electrical surges may be caused by lightning, large electrical machines or welding.

Every load cell should be shunted by a stranded copper cable to prevent welding currents from flowing through the load cell.